10ml Monodose Full Automatic Plastic Ampoules Filling and Sealing Machine for Olive Oil

Specification Product Description This machine is a kind of smaller type liquid filling and sealing machine, it's suitab

Description

Basic Info.

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Whole Life |

| Filling Volume | 1-50ml |

| Machine Weight | 900kg |

| Power Supply | 7kw 220V/380V 50Hz (Can Be Optional) |

| Cutting Speed | 0-25 Times/Min |

| Packing Material | PVC/PE, Pet/PE Combined Sheet (Thickness:0.2-0.4mm |

| Max. Forming Depth | 12mm |

| Transport Package | Wooden Case |

| Specification | 2300*850*1400 mm |

| Origin | China |

| Production Capacity | 360 |

Product Description

Specification

| Model | GGS-118 (2 filling head) | GGS-118 (5 filling head) |

| Max. Forming Depth | 12mm | 12mm |

| Cutting Speed | 0-25 times | 0-25 times/min |

| Packing Material | PVC/PE, PET/PE combined sheet (thickness:0.2-0.4mmx140mm) | PVC/PE, PET/PE combined sheet (thickness:0.2-0.4mmx140mm) |

| Filling Volume | 1-50ml | 1-50ml |

| Power Supply | 4.3kw 220V/380V 50HZ (can be optional) | 7kw 220V/380V 50HZ (can be optional) |

| Machine Weight | 700kg | 900kg |

| Machine Dimension | 1750×750×1400 mm | 2300×850×1400 mm |

This machine is a kind of smaller type liquid filling and sealing machine, it's suitable for small batch filling in pharmaceutical, pesticide, cosmetic, nutrition etc. field, it's widely used for filling oral liquid, perfume, liquid health care product etc.Main performance and structural features1. The machine adopts PLC control and stepless altering frequency adjustment.

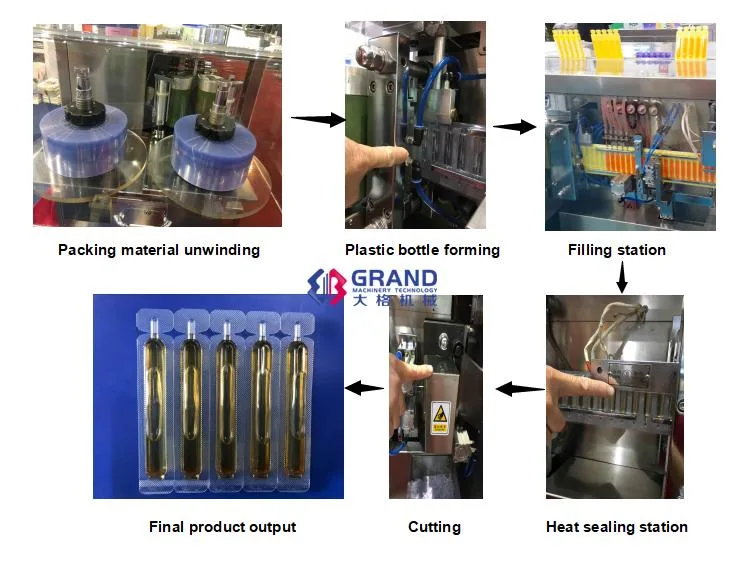

2. The machine can finish the following 6 working station automatically through the programmer, roller sheet release, PVC/PE forming, filling, press the batch number, back-end crop, slitting

3. The machine adopt the human-machine interface operation, operation is easy and simple

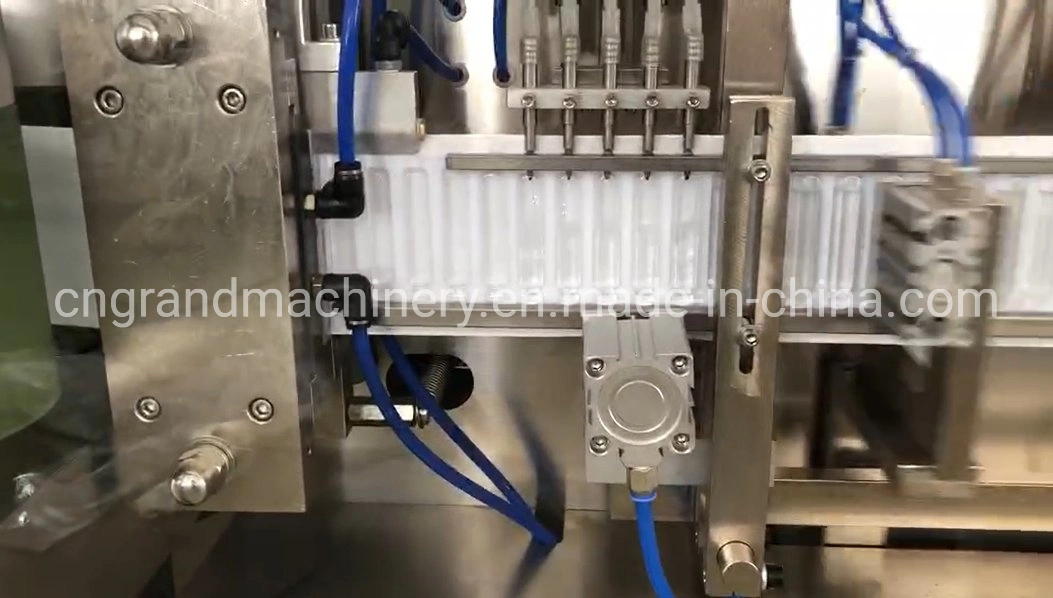

4. The filling head has no leak through, not appear foam and overflow.

5. The contact parts with the filled liquid adopt SUS316L, conforms to the GMP standard.

6. The main pneumatic component and electric parts adopt well-known brand products.

7. Filling system adopts mechanical pump, measuring is precisely and the difference is small.

Product Description

Factory

Wenzhou Grand Machinery Technology Co., Ltd. was established in 1999 by several experienced machinery experts, located in Wenzhou City, Zhejiang Province, China. Grand is specialized in R&D, manufacturing, exporting and providing related services of pharmaceutical equipment in solid preparation field. Main products includes grinder, granulator, dryer, mixer, capsule filling machine, tablet press, blister packing machine, bottle filling line, cartooning and encasing machine. Grand has over 5,000 meters standard producing plant and modern office, with more than 85 staff consisting of efficient producing team, experienced R&D team, professional sales team and thoughtful after sale team. Grand has passed the certification of ISO9001 and products have CE certification approved. Grand provides reliable quality, stable performance and thoughtful after-sales service, which attracted large number of customers covering more than 160 countries, such as, China domestic, Asia, Europe, America, Mid East and Africa. Our growth is inseparable from the trust and support of our customers. You are always welcome to our company for plant visitation, technology exchange and business cooperation.

PackageFAQQ1: What is your capability? Grand Machinery is a manufacturer of pharm and packing equipment. Qualified & high-level machines and packing solution & technology are our strengths over our competitors

Q2: How do you guarantee your quality and service? We have serious QC team to control the details from the small parts to the assembled machine. And our service and technical team are glad to answer and solve all problems if you meet during using our products.

Q3: What is your WARRANTY? One year warranty for the brand-new machine, and whole life after sale service, eg. spare parts, technical support etc.

Q4: How to pay? (Payment term) T/T, L/C, PayPal, Western Union, Cash even credit Card are all accepted

Q5: How long could you finish the machine after placing the order? (Delivery time) Normally: 15-30 days, if for stock products, it will be around 3 days.

Q6: Do you mind if we are agents? End users and agents are both welcome. And now we are recruiting Global Agents/Wholesalers!!! Join Grand Machinery & Discover More

Q7: More questions are appreciated Pls contact us freely if you have any other question or need.After Sales ServiceService1: We will take the professional videos for machine installation, operation and mould changing at our cost. This is unique service of us and ensures you the best machine running in the future.

Service2: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service3: We make guarantee of the machine for 12 months. During this warranty period, the seller will provide free spare parts that caused by the machine's quality within 10 days by fast courier upon receipt of buy's notice. we will also provide one set of spare parts/wear & tear parts to customer along with the shipment of the machine.

Service4: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Prev: Custom Mini Automatic Bottle Glass Ampoule Filling and Sealing Machine

Next: Automatic Aseptic Liquid Plastic Ampoule Forming Filling Sealing Machine

Our Contact

Send now