Pharmaceutical Cosmetic Laboratory Oxyhydrogen Flame Glass Ampoule Bottle Filling Sealing Machine

Description

Basic Info.

| Model NO. | OKABFKJ2-1-2 |

| Packaging Material Mechanical Properties | Full Automatic Filling and Sealing Machine |

| Material Type | Liquid |

| Fuel Consumption(M3/H) | Coal Gas 3-3.5m3/H; LPG 1.5-2m3/H; Combustion-Supp |

| Weight | 250kgs |

| Dimension(L*W*H-mm) | 1200*980*1350 |

| AC Voltage Requirement | 220V/380V |

| Rated Power | 0.55kw |

| Transport Package | Standard Export Package; 1set/Carton |

| Specification | 3600-3900pcs/hour |

| Trademark | Okay Energy |

| Origin | Changsha, China |

| HS Code | 8405100000 |

| Production Capacity | 500sets/Month |

Product Description

Pharmaceutical Cosmetic Laboratory Oxyhydrogen flame Glass Ampoule Bottle Filling Sealing MachineThe data sheet

| Model Number | OH100 | OH200 | OH300 | OH400 | OH600 |

| AC Voltage Requirement (V) | 220/110 | 220/110 | 220/110 | 220/110 | 220/110 |

| Phase | single | single | single | single | single |

| Rated Power(KW/h) | 0.4 | 0.8 | 1 | 1.4 | 2 |

| Max Gas Output | 100L/h | 200L/h | 300L/h | 400L/h | 600L/h |

| Max. Working Pressure (kg/cm 2 ) | 2 | 2 | 2 | 2 | 2 |

| Max. Water Consumption (L/h) | 0.06 | 0.1 | 0.16 | 0.21 | 0.33 |

| Water Feed | manual | manual | manual | manual | manual |

| Max. Flame Modifier Consumption (L/h) | 0.05 | 0.1 | 0.15 | 0.17 | 0.15 |

| Flame Modifier Feed | manual | manual | manual | manual | manual |

| Dimensions - L*W*H (mm) | 390*250*510 | 450*250*510 | 590*250*510 | 710*250*510 | 930*250*510 |

| Gross Weight (kg) | 15 | 20 | 25 | 35 | 45 |

| Ventilation Space Requirement (mm) | 200 in each direction | 200 in each direction | 200 in each direction | 200 in each direction | 200 in each direction |

Larger industrial

| Model Number | OH2000 | OH3000 | OH5500 | OH7500 | OH10000 | OH20000 |

| AC Voltage Requirement (V) | 380 | 380 | 380 | 380 | 380 | 380 |

| Phase | three | three | three | three | three | three |

| Rated Power(KW/h) | 6 | 9 | 17.5 | 23 | 31 | 70 |

| Max Gas Output | 2000L/h | 3000L/h | 5500L/h | 7500L/h | 10000L/h | 20000L/h |

| Max. Working Pressure (kg/cm 2 ) | 2 | 2 | 2 | 2 | 2 | 2 |

| Max. Water Consumption (L/h) | 1.07 | 1.6 | 2.8 | 4 | 5.6 | 11.6 |

| Water Feed | auto | auto | auto | auto | auto | auo |

| Dimensions - L*W*H (mm) | 1070*670*1000 | 700*1100*1280 | 750*1300*1650 | 850*1300*1820 | 1050*1400*1900 | 2300*1100*1800 |

| Gross Weight (kg) | 210 | 300 | 396 | 552 | 610 | 1400 |

| Ventilation Space Requirement (mm) | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction |

Automatic ampoule filling and sealing machine specifcations

| Model | OKABFKJ2-1-2 |

Available Heads | single head/double head |

Production Capacity(Pieces /Hour) | 3600-3900 |

Power Consumption(KW/H) | 0.55 |

Ampoules | 1-20ml |

Fuel Consumption(m3/h) | Oxy-hydrogen gas 1-1.5m3/H |

Dimension(L*W*H-mm) | 1200*980*1350mm |

AC Voltage(V) | 220V 50-60 Hz |

Weight(KG) | 250 |

| Photo |

|

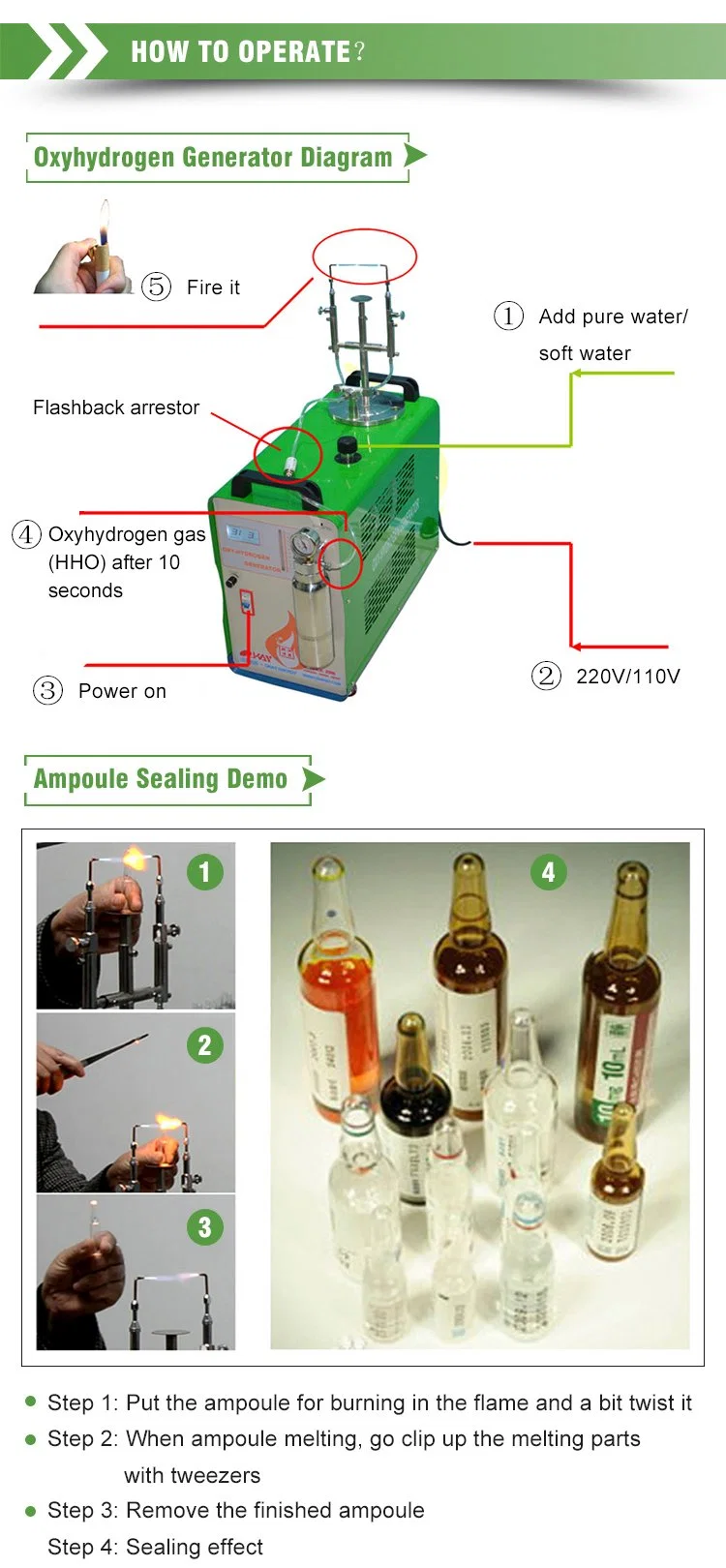

Traditional ampoules sealing machine adopts liquid gas as fuel and air as combustion-supporting gas.The producted flame contains carbon dioxide, carbon monoxide and nitrogen compounds,these substances will impact on the quality of pharmaceuticals and bring security hidden danger to work environment. According to the request of scientific research personnel, Our Okay Energy Equipment Co.,Ltd adopts Oxy-hydrogen generetor to seal the ampoules.

Oxyhydrogen Glass Ampoule Sealing Machine technology uses water as medium to electrolyze water into H2 and O2, fire them to formed Oxyhydrogen Flame. The temperature of Oxyhydrogen flame is as high as 2800 degrees so that it can seal the Ampoules very fast. The quality and speed of Oxyhydrogen Flame sealing method is higher than Liquid gas's.

Oxyhydrogen Features and Advantages for ampoule sealing

1. Safety Oxy-hydrogen Flame Ampoules Sealing Machine just uses water and electricity, no gas bottle, no hydrogen gas storage, no leakage and explosive danger.

2. Convenience it can work just with water and electricity, every litre water can be used 7~8 hours. But Liquid gas bottle need to be changed by manual moving, it is very inconvenient.

3. Cleanliness Oxy-hydrogen combustion just produces little water vapour, there is no harm to the pharmaceuticals. But Liquid gas combustion produces carbon dioxide, carbon monoxide and nitrogen compounds which will impact on the quality of pharmaceuticals.

4. High Efficiency The speed of Oxy-hydrogen Flame sealing method is higher than Liquid gas's.

Shipment and PackageAbout shipping We have long-term cooperated shipping counrier providing one-stop safety and quick shipping service.Flexible Shipping method by international express(DHL,Fedex,UPS etc),by air,by sea as your requirement.Or using your shipping forwarder.About Package Standard export package,1set/carton;For industrail larger machine,1set/woodern pallet;

Machine accessories for free

Torch and nozzle: 1 setSoft pipe: 2mFlame arrester: 1 unitOkay Service1.24hour online chat,email or phone support for inquiry,technical and after-sales service;2.Warranty:1year.(The core part of machine for 1year.The other parts of machine for half of year in addition to human damage;3.online trade assurance service(Protection buyer's payment regarding on-time delivery and product quality.)Company IntroductionOkay Energy Equipment Co.,Ltd is one of the largest manufacturers in producing oxyhydrogen generator for over 13 years, we have autorized CE,ISO9001 certificates and our own patents.We provide the best service and high quality products to our customers. If you have any questions, pls don't be hesitate to contact us.

Our Contact